What would you do if you not only had the money but if you had the technology to build a completely working and fully functional superhero outfit?

Over the years, we have seen some very impressive cosplayers create some amazingly authentic superhero costumes that rival the ones we have seen on the big screen. But the one thing all of them always seem to fail on is making their outfits viable enough to be considered a realistic option to wear in the real world.

That said, assuming superheroes are not as real as they are in the Marvel Cinematic Universe, will we ever be able to put together and construct the same superhero outfits we have seen fighting the bad guys for years?

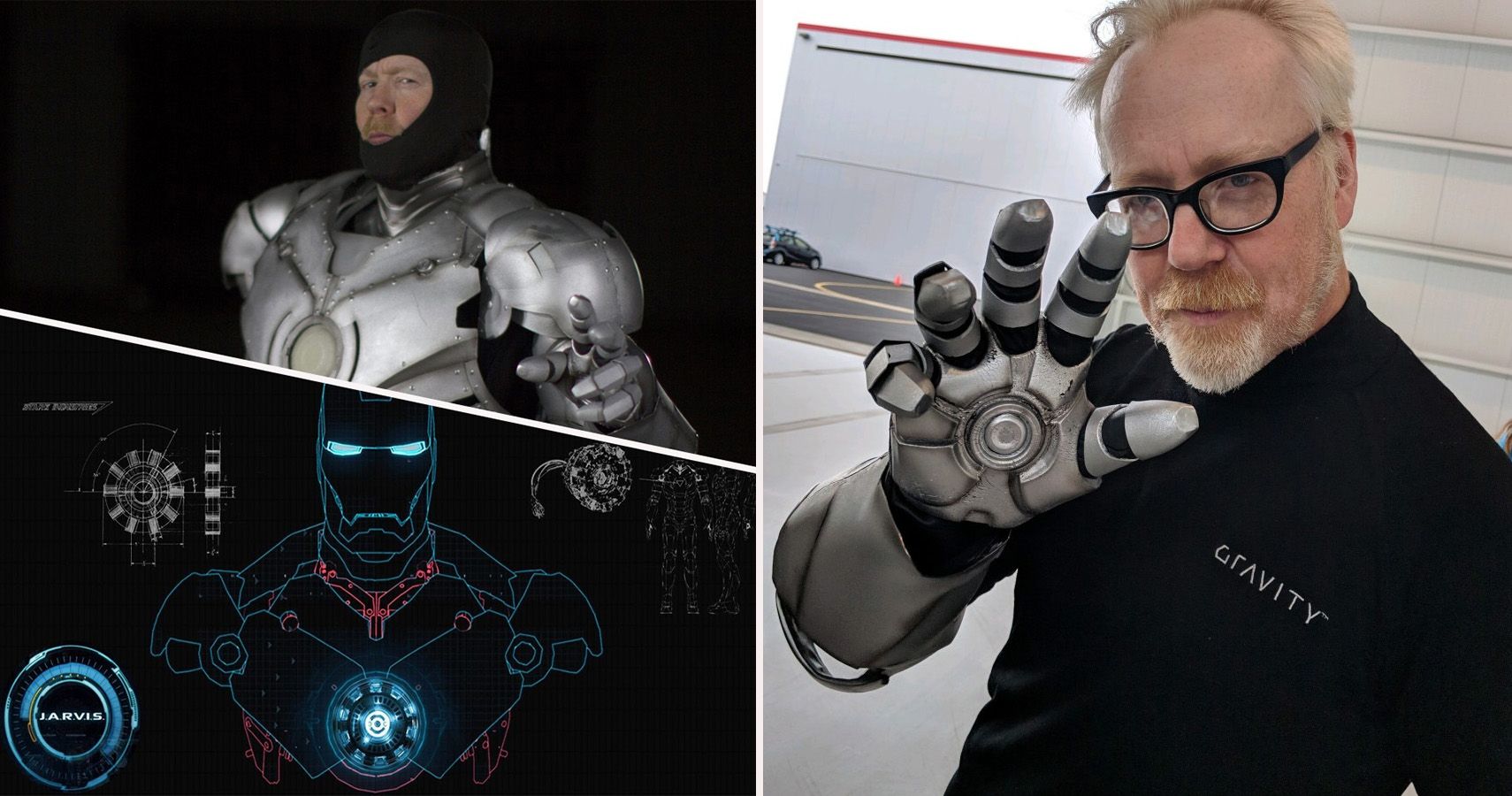

Adam Savage has done it. He has built the world's first fully functional Iron Man outfit which comes complete with the ability to fly and defend against bullets. We did the research and found the facts you need to know about.

20 Nearly 280 Individually Printed 3-D Parts

In order to create something that gives a human being the ability to move around and bend at all the right places, you need to have a lot of parts. That would give you a lot of mobility and also create something that is very authentic.

So that means that if they wanted to create the perfect Iron Man suit of armor using titanium 3-D parts, it would take a ton of them. The builders have estimated that it took about 280 individually printed 3-D parts that came together to make the suit a reality.

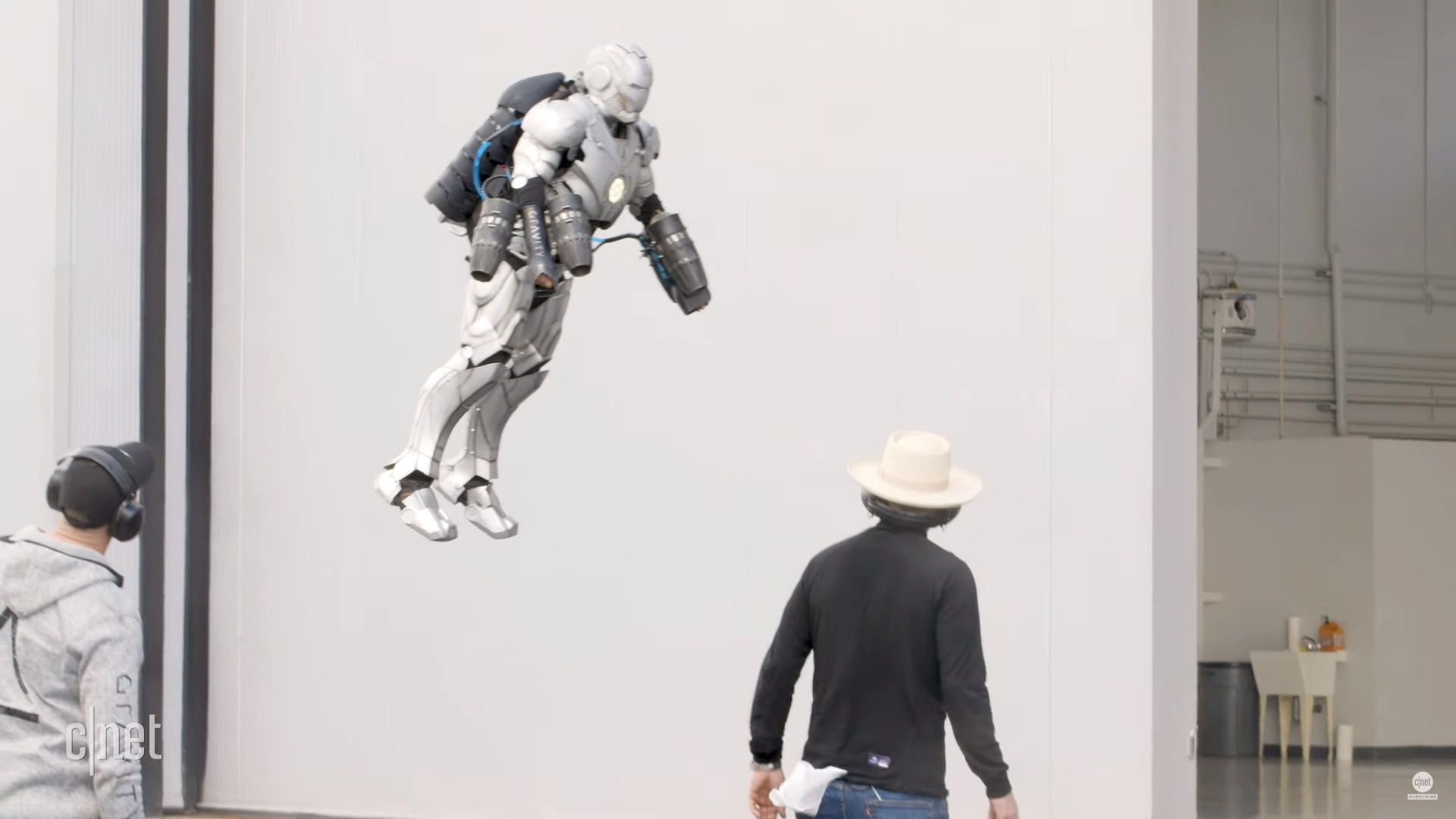

19 We Are Going To Need A Ton Of Space

Knowing that this was going to be a ground-breaking build for Adam, he knew he would need a lot of space to be able to test the suit safely.

Normally, on Mythbusters, whenever they need the extra space, they would go to the abandoned Naval Air Station in Alameda. But for this show, he decided to use an airport hangar instead. This allowed them to construct a safety harness when Adam was testing out the jets for the first time.

18 It Is Safer Underneath The Suit

Although the outside of the titanium Iron Man suit looks like it would be really heavy, it is not. It is very light and bendable all across the body, allowing the user to really get around in the outfit.

However, underneath the suit, there are a few safety precautions that were built in, including belts that strap across the chest and back of the user to help protect their body in case of jet failure.

17 The Lighter, The Better

Since safety is always a concern, how are they able to build the entire Iron Man suit of armor and keep it light enough to be able to work correctly?

It is simple: keep the suit under 20 pounds. That is the line that they kept the suit underneath in order for it to be viable. But making a 280 part titanium suit weigh less than 20 pounds was not easy. How did they do it?

16 Thinner Than A Piece Of Human Hair

Since they knew that they needed to make it as light as possible, they had to make it thin, but strong. So using the titanium in the 3-D printer required them to use a laser beam to melt the metal into powder. The powder ends up being about 40 microns in diameter.

To give you a better idea of what 40 microns looks like, it is about half the diameter of a piece of human hair. So when they said thin, they really meant it.

15 The Modern Age Rocketeer Suit

The coolest piece of the entire Iron Man suit that Adam Savage helped construct are the jet packs attached to the arms. These jet packs are the key to the entire suit of armor being a viable option for actual everyday use in today's world.

The suit includes five mini jet engines, each of which has 1,000 horsepower. They were built by Gravity Industries specifically for this outfit in a joint effort because Adam is not the only person who wants to see this thing get built.

14 Visibility Is An Issue

After his first successful run, Richard Browning had a few very important improvements that he wanted to talk about. The first one being the eyesight and lack of visibility.

When Richard landed, and took off the helmet, the first thing he mentioned was that he could not see a thing. He was basically going off memory when flying around the hangar and then landing on the platform they setup earlier in the trial.

13 The Shins Bend Like A Banana

Another issue that bothered Richard Browning was the shin parts, which were built to replicate the Iron Man suit from the movies. Since they went for authenticity over comfort, the leg parts covering the shins bend inward, like a banana.

So imagine squatting down and those parts pushing into your legs cause the shins do not bend outward. They do not conform to the suit and are pretty painful when landing, according to Richard.

12 Do Not Try To Shoot It Down

When Adam Savage received the chest portion of the Iron Man suit to test its durability against bullets, he decided that he needed to try a few different bullet sizes.

He shot guns with a .22 caliber bullet, a 9mm, and a .45 caliber in order to see just how tough this suit was built. As it turns out, it protected against all three sizes, making it even more amazing.

11 The Noise Will Bother Some People

If you think it looks cool, you should also consider that five mini jet engines, even as small as the ones on the suit, are going to be loud, very loud. But that is something they can always work on for future builds.

As of now, if they were to take this out to use in public, you could hear it coming from a mile away. It could not be used for any missions requiring the use of stealth.

10 How Long Can You Stay Up There?

Without ever having anyone build a flying Iron Man suit of armor, there was no way to know just how long you would be able to fly around wearing the thing before falling out of the sky, like a crashing plane.

But after considering the use of the jet engines, the weight of the person wearing the suit, and the suit's overall durability, they decided that 90 seconds would be the maximum amount of time for these trials before coming back down to the ground.

9 Don't Go Higher Than 15 Feet Off The Ground

Now that we have an idea on the amount of time they can stay flying around in the Iron Man suit of armor, the next thing is to consider just how far off the ground is a safe distance before the jet engines would not be able to work correctly.

If you were to go above 15 feet, the control of the jet engines would loosen and you could end up crashing straight into the ground. As long as you stay within that space, you should have no issues keeping control over the suit.

8 Richard Browning Got To Do It First

Adam Savage was able to test the jet engines of the suit without ever putting on the suit. This showed him just how tough it was going to be to operate the Iron Man suit and he decided that it would be better tested by the man behind the company that built the jet engines, Richard Browning.

It was Richard who got to put on the Iron Man suit and test it out before anyone else, making him the first person to ever take a ride in the suit.

7 95% Is Not Quite 100%, But It's Close

The most important piece of the entire Iron Man suit of armor was the titanium they used to build it using a 3-D printer. That was the difference. Without titanium, this suit would never have gotten built correctly.

Adam knew that and that was why he came up with the idea the moment he found out about a 3-D printer that was capable of printing models using the metal.

6 Marvel Provided All The Details

After Adam Savage reached out to Marvel about this idea to use 3-D technology to build the Iron Man suit, they gladly responded by providing him with all the information they needed to replicate the same Iron Man costume we see in the movies.

They gave the show all the measurements, insight, and tips on what they did to build their own versions in order to keep it as authentic as ever.

5 Tony Stark Would Build This Today

In a today's world, if superheroes were flying around saving lives and protecting the planet from villains like Thanos, and they were only able to use the technology available today, then this suit would be the exact thing Tony Stark would have built.

Although we can easily assume that Tony Stark's super intelligence would help him take that technology and make it better, he would still rely on what is already available to him and create the version built by Adam Savage.

4 The Man Behind Mythbusters

Adam Savage has done just about everything throughout his career. He was an animator, projectionist, set designer, editor, actor, writer, toy builder, graphic designer, carpenter, model maker, and television presenter who is most famous for co-hosting the hit Discovery Channel show, Mythbusters.

For 14 years, he helped prove, and disprove, some of the most popular myths in pop culture today. His talents always seemed to shine brightest when given the freedom to build things. This has led to his latest show, Savage Builds, which debuted on the Science Channel in June.

3 Savage Builds Brings Fantasy To Life

The latest series hosted by Adam Savage debuted in June on the Science Channel and featured eight episodes of him doing things we did not think was possible. Savage Builds allows him to do the things he always wanted to do on Mythbusters without having to worry about proving anything besides whether or not he can do it.

The show debuted with his attempt at building a fully functional Iron Man suit of armor that is not only bulletproof, but can fly.

2 The Colorado School Of Mines Loves Iron Man

The idea for building the Iron Man suit of armor came while Adam Savage was visiting the Colorado School of Mines. A professor, Craig Brice, was showing him around the campus when an idea popped into Adam's head.

That idea became a reality when Adam asked Craig if he was interested in helping build him an Iron Man suit for his new show using one of their 3-D printers. From there, it was all about getting the plans and making it as authentic as possible.

1 EOS, Global Leader In 3-D Printing Of Titanium

Electro Optical Systems, EOS, has been a German manufacturing company since 1989 when two doctors got together and decided to start something that would lead the way in innovation.

At the time, 3-D printing was more of a pipe dream, but once it became something doable all over the world, they decided to get involved and figure out a way to print titanium better than everyone else. That made them the easy choice for the building of this Iron Man outfit.